|

Xiang In offers two major types of decoration choices including heat transfer film and IML Labels. We have abundant experience on producing heat transfer film and IML in-mould labeling in variety of industries including stationery, cosmetics, oral care, consumer electronics, food packaging…etc. Please let us know what kinds of semi-product that you are going to apply, we will give you the film selecting suggestion accordingly. |

|

|

Firstly, we would make sure that we have fully understanding on clients’ need, including the applied product, material, size and the graphic design. We believe that ensuring customers’ demand is vitally important for heat transfer film supplier and In-mold Label(IML) manufacturer, If you can fully understand what customer need, want and what are they going to do with your IML or heat transfer film, you could have a higher chance to avoid some mistake happened. |

|

|

Confirming the final artwork with our clients is essential for us, which includes confirming the exact size, dimensions and numbers of color for the heat transfer film or In mould Label. |

|

|

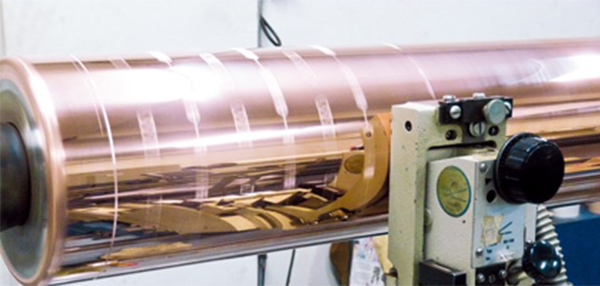

Rotogravure Cylinders printing is a long run and high-quality printing method, cylinder is etched with cells of different depths, and these cells hold the ink that is transferred to the heat transfer film or IML (In Mold Labeling). Therefore, it’s unchangeable once the cylinder been engraved, and this the reason the final artwork confirming is essentially important for us and our clients.  *At this stage, we will make a charge for any modification for the cylinder. |

|

|

In this section, we will provide the simple which is match to your request on size, position, color for In-mold Labeling or heat transfer film, client can confirm the artwork has correct colour and appropriate bleed settings on the IML or HTF. Processing fee will be generated at this process, but we strongly recommend our clients to do the sample proofing every time when they place their order in order to ensure they can receive what they ask for. |

|

With our advanced printing equipment and abundant experience on IML and HTF manufacturing, we are pretty confident that we are able to satisfy the clients’ demand. |

|

|

Die-cutting or slitting per sheet or package while respecting the size of labels with unparalleled accuracy. We insist on taking strict inspection management for offering customers the In-mould label and heat transfer film in excellent quality. |

|

Routing marked, sorted, and protected packages, guaranteeing the integrity of your product upon reception. |

|